What is the Recycling of Electric Vehicle Batteries?

Recycling of electric vehicle batteries is a process that helps to reuse EV batteries rather than becoming waste. Instead of trashing the used batteries, recyclers break them into parts to separate and purify the metals. Recycling of electric vehicle batteries allows for the extraction of valuable components from the end-of-life EV battery pack to be circulated back to the economy.

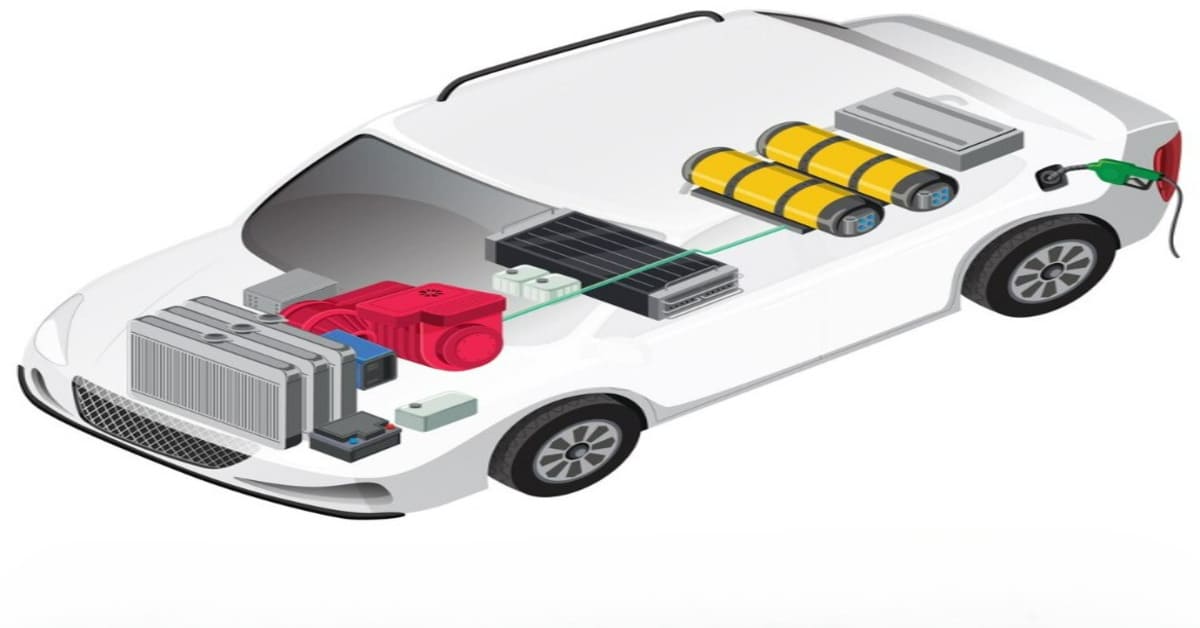

What are EV Batteries Made of?

Electric vehicle batteries, mostly lithium-ion batteries, are generally made up of cathode materials (which include nickel, cobalt, manganese, and lithium), anode materials (mostly graphite), electrolytes, and other materials like steel, aluminum, copper, plastic, polymers, etc. By following the appropriate process, the company recycles all the materials for electric vehicle batteries.

Purpose of Recycling Electric Vehicle Batteries

The purpose of recycling of electric vehicle batteries is to recover materials and protect natural resources. It reduces environmental impacts, carbon footprints, and the long-term cost of battery manufacturing.

Steps to Recycling Electric Vehicle Batteries

The recycling process of electric vehicle batteries typically follows these steps:

- Collection and Transportation of Dead Batteries

- Disassembly of the Battery Pack

- Shredding or Crushing Batteries

- Separate Materials

- Refinement Process for Retrieved Materials

- Reintroduced Raw Materials to the Manufacturer

Now lets us discuss the the above steps of recycling electric vehicle batteries in details:

1. Collection and Transportation of Dead Batteries

First, battery manufacturers need to collect used EV batteries and transport them to recycling factories.

2. Disassembly of the Battery Pack

They follow the process to disassemble and separate the modules of the battery pack, and they should discharge the all-battery cells.

3. Shredding or Crushing Batteries

They follow the process of crushing the batteries to extract the internal materials.

4. Separate Materials

With the use of physical and chemical processes, from the shredded or crushed batteries, they separate materials like lead, lithium, cobalt, nickel, copper, and plastics.

5. Refinement Process for Retrieved Materials

The retrieved material goes through a refinement process to enhance its purity for reuse.

6. Reintroduced Raw Materials to the Manufacturer

After the completion of the refinement process, the refined materials, like metal alloys, plastic, copper, and lithium compounds, are reintroduced to the manufacturer as raw materials for further use as new EV batteries. Recycling electric vehicle batteries is an opportunity to protect finite resources, reduce environmental impact, and improve the sustainability of electric mobility. With the increasing demand for electric vehicles, the demand to recycle electric vehicle batteries is experiencing an awe-inspiring surge.

Methods of Recycling Electric Vehicle Batteries

There are basically three methods for recycling electric vehicle batteries:

- Pyrometallurgy

- Direct Recycling

- Hydrometallurgy

1. Pyrometallurgy

Pyrometallurgy is the process of heating ore at high temperatures to extract materials. It extracts 50–60 percent of minerals such as nickel and cadmium. Its recovery rates for lithium, manganese, and aluminium are very low. It has the highest impact on the environment and uses a lot of energy, so it is the least ideal technology for recycling electric vehicle batteries.

2. Direct Recycling

Direct recycling aims to extract a large proportion of materials from used batteries. It lowers energy consumption, environmental impact, and greenhouse gas emissions. Direct recycling has a recovery rate of up to 90% for nickel and cobalt and 50% for lithium. It is best suited for lower-value batteries such as lithium-iron phosphate.

3. Hydrometallurgy

Hydrometallurgy, also known as mechanical pre-treatment, is used to extract black mass. We need to leach with the use of reagents and solvents. Moreover, it requires metal disposition through chemical or electro-extraction to extract materials, and its recovery rate goes up to 95%, so it is considered the ideal technology to recycle electric vehicle batteries.

Benefits of Recycling Electric Vehicle Batteries

Recycling batteries is one of the most useful ways to reuse spent batteries. There are several reasons to understand why recycling of electric vehicle batteries is useful:

- Environment Impact

- Reuse Scarce Materials

- Reduce Waste

- Sustainability Goals

- Raw Materials

- Long-Term Viability

- Reduce Dependency on Importing Minerals.

Please find the below explanation of the benefits of recycling electric vehicle batteries

1. Environment Impact

Electric vehicle batteries contain several materials like lithium, cobalt, nickel, and manganese, which need intensive mining. Recycling reduces the need for new mining and contributes to protecting the environment from hazards. It is a tangible way to preserve the environment.

2. Reuse Scarce Materials

Some of the key materials used in electric vehicle batteries are in short supply. Recycling helps to reuse valuable and scarce materials.

3. Reduce Waste

If you do not recycle the used EV batteries, that would contribute a huge amount of waste, leading to soil and groundwater contamination, so recycling spent batteries minimises waste and promotes decarbonisation.

4. Sustainability Goals

Recycling EV batteries improves sustainability, leading to electric mobility and reducing environmental impacts.

5. Raw Materials

Recycled materials can feed back into the battery supply chain, increasing the raw materials needed to produce electric vehicle batteries.

6. Long-Term Viability

A robust recycling programme is helpful to address concerns about the long-term viability of EV battery waste.

7. Reduce Dependency on Importing Minerals

Recycling helps reduce our dependency on importing mineral reserves. It aids in boosting the economy and generates revenue for the country.

Challenges in the Recycling of Electric Vehicle Batteries

There are several key challenges involved in the recycling of electric vehicle batteries:

- Battery Pack’s Complex Design

- Material Recovery

- Safety Protocols

- Cost Competitiveness

- Second-life Challenges

- Stringent Government Policies

Please check the detailed overview of the above points:

1. Battery Pack’s Complex Design

A battery pack needs hundreds of cells to make it, and its complex design makes it difficult to separate and disassemble. The components of electric vehicles are made of several materials.

2. Material Recovery

Recovering materials like lithium, cobalt, and nickel from used batteries needs an advanced process. Improving overall material recovery rates is an ongoing challenge.

3. Safety Protocols

Recovering materials from used lithium-ion batteries can be hazardous, as it may lead to reactive batteries. It may cause a fire as a result of chemical and electrical hazards. We should follow stringent safety protocols and specialised equipment to avoid any mishaps, as the process of testing the waste battery takes huge risks.

4. Cost Competitiveness

Recycling electric vehicle batteries requires a high cost compared to using new mined materials. The efficiency of recycling batteries is crucial. Scaling up the recycling process to remove EV waste volume is the need of the hour.

5. Second-life Challenges

Building secondary markets for second-life batteries is also difficult, as assessing used battery packs before recycling poses technical hurdles. The lack of harmonized regulations for electric vehicle battery recycling creates uncertainties for industries.

6. Stringent Government Policies

The Ministry of Environment oversees the recycling of electric vehicle batteries, and its stringent rules for land usage make it more complex.

Overcoming these recycling hurdles is critical to long-term sustainability. The dearth of infrastructure for recycling electric vehicle batteries is one of the issues, leading to a single-digit percentage of battery recycling.

The Future of Recycling Electric Vehicle Batteries in India

A study conducted by the Confederation of Indian Industry (CII) shows that tonnes of waste batteries will reach recycling firms by the end of 2030.

In the coming years, the market for recycling electric vehicle batteries will be lucrative, as when materials are extracted after purification, they can be efficiently used further. With the significant growth of electric mobility, the demand for recycling electric vehicle batteries increases as it provides second-life opportunities for batteries.

You may also want to read:

10 Recycling Lithium-ion Battery Companies in India

12 Effective Tips for the Maintenance of Electric Vehicle Batteries

Batteries For Electric Vehicles

Wireless Charging for Electric Vehicles (EV)

Conclusion

Efficient recycling programmes for EV batteries can reduce their environmental footprint, improve sustainable growth, enhance economics, and meet regulatory standards, thereby enhancing the mass adoption of electric vehicles. Many regions are focusing on developing policies to recycle EV batteries. Recycling of electric vehicle batteries helps to reuse degraded batteries for energy storage. Recycling processes with lower environmental impact and a higher recovery rate will reduce the need for new mining by 2050.